Betek TungStuds with tungsten carbide core: effective protection against wear for metal surfaces

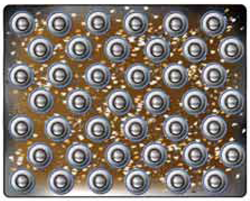

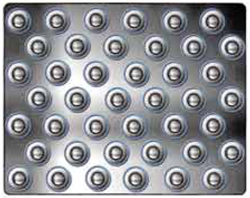

Whenever the ground is being dug or worked, BETEK TungStuds are right on the front-line. Fitted with a tungsten carbide core, the TungStuds are the first to come into contact with the excavated material and are exposed to extreme abrasion. In addition to protection against wear being provided by the TungStuds, the material packed between them is also used as a buffer. This reduces direct wear on the metal surfaces caused by material movements.

Instead of expensive spare parts being required due to worn metal surfaces, it is just the TungStuds that have to be replaced. When using BETEK TungStuds expenditure on maintenance is also lower, as thanks to their tungsten carbide core they can withstand even the most extreme conditions.

Betek TungStuds form optimum |

A Betek TungStud is welded on |

In the course of the digging work, |

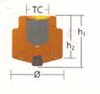

Welded on with ceramic ferrule |

High performance included

On request, we can also provide you with the appropriate

stud-welding machine for your TungStuds.

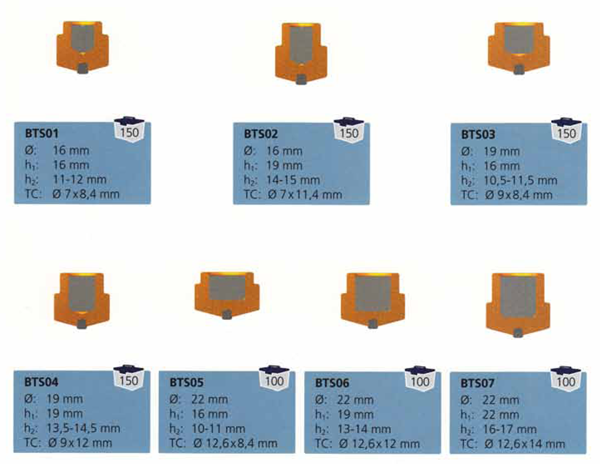

Please ask us if you need any different sizes. We will

also gladly explain to you the typical areas of use for

the TungStuds shown here.

|

h1 : height before being welded on h2 : height after being welded on |

TungStuds range

First choice for numerous applications: Betek TungStuds

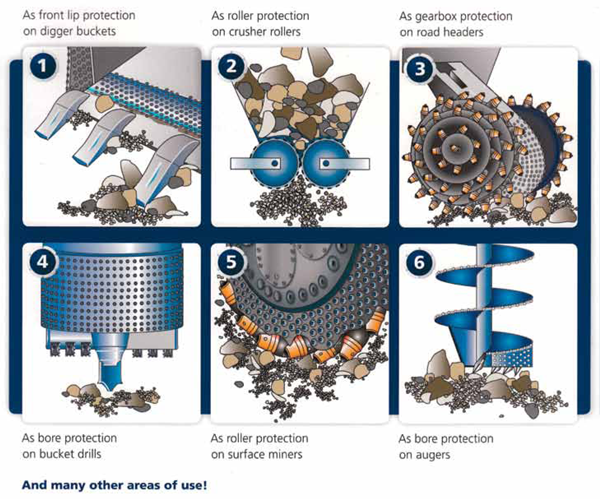

The application illustrated above are just a few examples of the wide range of areas in which the user of TungStuds brings major benefits. Wherever metal surfaces are exposed to extreme conditions, TungStuds reduce operating costs. Expensive machine parts get protected and can be utilised longer.

TungStuds also provide top protection against wear even if the material being dug up is bulkier and no rock box effect is formed across the tool.