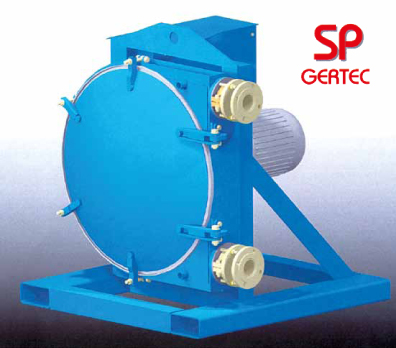

Hose pomp

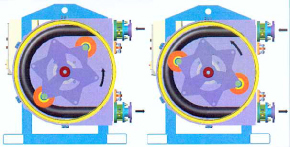

Principle of Operation

The Principle of Operation of the GERTEC Hose Pumps is based on the principle of peristaltic delivery, i.e. the ability of the pump hose to restore its initial shape sfter each crush.

While the rotaring pressure roller is crushing the ose pump by running over it, the suction side is disconnected from the delivery side. The rising of the hose pump after each crush creates a cavity, wich causes a suctioning of the delivery medium. Simultaneously, the delivery medium is squeezed out of hose pump on the pressure side

Technical and Economic Advantages

Easy and economical pumping of fluids containing a high proportion of solids; abrasive, corrosive and viscous mediums as well as mediums sensitrive to shearing.

- Self-priming up to an 8 meter suction height.

- Capability of running dry.

- Reversible rotating direction.

- No valves.

- Only one part that comes into contact with the product (pump hose).

- Easy and rapid hose replacement.

- A sturdy construction and dimensioning of pump, designed purposely for construction sites.

- Without demixing or mechanical demolition of pumping medium.

- Compensation of abrasion of pump hosethrough easy eccentric adjustment.

- Appropriate for opération with or without hose greasing.

- A wide range of different driving units

- appropriate for the respective application (electric drive constant spedd; electric drive switchable speed; continuously adjustable mechanical; electrical or hydraulical driveng units diesel engine).

- Easy operation and maintenace.

- Low operating costs.

| PUMP TYPE |

Drive |

Pump Capacity

max.

|

Delivery Pressure

max.

|

Suction Height

max.

|

Grain Size

max.

|

Power Input |

Rotational Speed |

Nominal Diameter of Pump Hose |

Lenght |

Width |

Height |

Weight |

| |

|

M³/H |

BAR |

M |

MM |

KW |

RPM |

MM |

MM |

MM |

MM |

KG |

| SP-350-1 |

1 speed |

4.2 |

3 |

8 |

4 |

1.5 |

110 |

35 |

540 |

420 |

870 |

65 |

| SP-350-2 |

2 speeds |

2.1/4.2 |

3 |

8 |

4 |

1.4/1.9 |

55/110 |

35 |

540 |

420 |

870 |

65 |

| SP*550-1 |

1 speed |

9.6 |

3 |

8 |

4 |

3.0 |

70 |

50 |

700 |

500 |

1000 |

105 |

| SP-550-2 |

2 speeds |

4.8/9.6 |

3 |

8 |

4 |

2.6/3.1 |

35/70 |

50 |

700 |

500 |

1000 |

105 |

| SP-700-1 |

1 speed |

14.0 |

8 |

8 |

16 |

7.5 |

67 |

50 |

1050 |

1000 |

1100 |

730 |

| SP-700-2 |

2 speeds |

7.0/15.0 |

8 |

8 |

16 |

6.5/8.0 |

36/72 |

50 |

1050 |

1000 |

1100 |

730 |

| SP-900-1 |

1 speed |

30.0 |

8 |

8 |

24 |

18.5 |

66 |

70 |

1250 |

1420 |

1420 |

1080 |

| SP-900-2 |

2 speeds |

15.0/30.0 |

8 |

8 |

24 |

13.0/17.0 |

34/67 |

70 |

1250 |

1420 |

1420 |

1080 |

| SP-1100-1 |

1 speed |

48.0 |

8 |

8 |

32 |

22.0 |

37 |

100 |

1650 |

1640 |

1640 |

1870 |

| SP-1100-2 |

2 speeds |

24.0/48.0 |

8 |

8 |

32 |

18/37 |

18/37 |

100 |

1650 |

1640 |

1640 |

1870 |

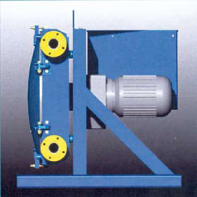

Standart Equipment

GERTEC Hose Pumps are ready for use and consist if the following main components:

- Stable, airtight pump housing with swivelling cover.

- Pump rotor mounted with 21 opposite pressure rolls and guiding rolls.

- Pressure roller withlarge roller bearings and eccentric adjustment

- pump hose, hose clamping, suction connection, pressure connection.

- Gearbox motor with strengthened bearing.

- Steel base frame with fork lift pockets and a central lifting eye.

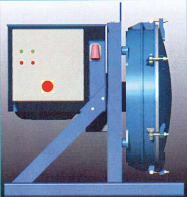

- Hose break supervision.

- Vaccum unit for the increase of the suction ability.

- Pulsation muffler with pressure gauge.

- Electrical control.

Accessories

Accessories

- Cable remote control

- Suction filter

- Tool box

Special Design

- Back-geared motor on special voltage

- Certificate : ATEX, CSA, NEMA, UL

- Diesel-hydraulic motor

- Continuously variable engine speed variation

- High pressure version (25 bar)

- Chassis

Operative Ranges

Operative Ranges

- Civil engineering

- Tunneling

- Separation

- Mining

- Chemistry

- Paper industry

- Ceramic industry

Range of Applications

- Pumping of fluids (bentonite, cement, anhydrite floor, flue ash, diaphragm wall, cutoff wall, high-pressure injection)

- Pumping of slurry

- Dirty-water pump

- Charging separation plant, centrifuge, filter press

- Pumping mortar, floor pavement, lime and concrete

- Cavity filling

- Pumping glaze

Copyright Geotechno 2026 -