Polymeren

|

POLYCOL 60 S

USE

Viscosifier for drilling muds, easy to mix and very simple to use. Stabilize the hole walls, remove cuttings, increase core recovery in less consolidated formations.

FORM

Powder form product. Available in 500 grs, 1 Kg, 5 Kg, 25 Kg bags.

|

ADVANTAGES

- Little storage and low concentrations: 0,5 to 1,5 Kg/M³ of water, to obtain 40 to 90 sec marsh viscosity.

- Non toxic, non polluting polymer.

- Easy to mix.

- Avoid cake, there is no warping in water well drills.

- Reduce torque on inhole equipment.

- Improve drilling penetration rates.

- Better cuttings removal.

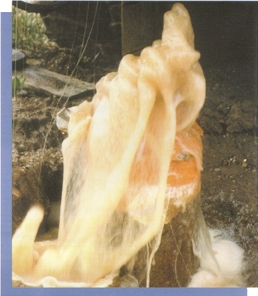

- Better core recovery in unconsolidated formations: when POLYCOL 60 S is diluted in water, it produces long molecular chains which deposit on the hole and core, increasing stability and integrity.

- Easy to destroy, by adding bleach or hydrogen peroxide (2l/M³ of mud).

- For fresh water only. For salted water, use POLYCOL 60 SM.

NATURE

Blend of polyacrylamides/sodium acrylates.

INSTRUCTIONS FOR USE

Determine the concentration:

- 0,5 Kg/M3 for hard rocks

- 1 Kg/M3 for instable layers

- 1,5 Kg/M3 for 100% core recovery in sandy, friable sandstones, powdery schists, gravels, alluvions

Pour POLYCOL 60 S slowly on a jet of water, or use a mixer. Do not use shale shakers to carry off cuttings from the mud.

When drilling, the polymer deposits on the sides of the hole, core and the cuttings to stabilize the walls, so it is necessary to add some product time to time when viscosity falls.

If the viscosity decreases too rapidly, maybe there is a problem of acidity. Add 0,2 Kg of soda ash by M³ of mud. POLYCOL 60 S is compatible with nearly all kinds of polymers for drilling muds. It’s incompatible with Bentonite and attapulgite muds.

|

POLYCOL 60 LS

USE

Viscosifier for drilling muds, easy to mix and very simple to use. Stabilize the hole walls, remove cuttings, increase core recovery in less consolidated formations.

FORM

Liquid form product. Available in 5 Kg and 25 Kg cans.

|

ADVANTAGES

- Little storage and low concentrations: 1,0 to 3,0 litres/M3 of water, to obtain 35 to 70 sec marsh viscosity.

- Non toxic, non polluting polymer.

- Reduce torque on inhole equipment.

- Avoid cake, there is no warping in water well drills.

- Improve drilling penetration rates.

- Better cuttings removal.

- Better core recovery in unconsolidated formations: when POLYCOL 60 LS is diluted in water, it produces long molecular chains which deposit on the hole and core, increasing stability and integrity.

- Easy to destroy, by adding bleach or hydrogen peroxide (2l/M3 of mud).

- For fresh and salted water.

NATURE

Blend of polyacrylamides/sodium acrylates in emulsion.

INSTRUCTIONS FOR USE

Determine the concentration:

- 1,0 litre/M3 for hard rocks

- 2,0 litres/M3 for instable layers

- 3,0 litres/M3 for 100% core recovery in sandy, friable sandstones, powdery schists, gravels, alluvions

Pour POLYCOL 60 LS directly in water. The mud is ready immediately. Do not use shale shakers to carry off cuttings from the mud.

When drilling, the polymer deposits on the sides of the hole, core and the cuttings to stabilize the walls, so it is necessary to add some product time to time when viscosity falls.

If the viscosity decreases too rapidly, maybe there is a problem of acidity. Add 0,2 Kg of soda ash by M3 of mud. POLYCOL 60 LS is compatible with nearly all kinds of polymers for drilling muds. It’s incompatible with Bentonite and attapulgite muds.

|

USE

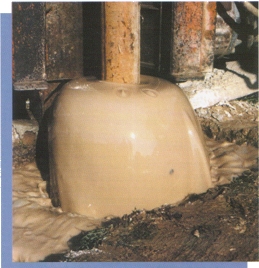

Foaming agent for air drilling.

Removes cuttings, stabilizes the hole walls. Prevents marls and clays from swelling and sticking.

FORM

Liquid form product.

Available in 20 and 25 Kg cans.

|

ADVANTAGES

- Little storage and low concentrations: 3,0 to 7,0 litres/M³ of water, to obtain high foaming properties.

- Easy to mix: liquid form.

- Stabilize the hole walls in clays, marls and poorly consolidated formations.

- Non toxic, non polluting, biodegradable product.

- It is possible to increase the hole stability in unconsolidated layers by adding POLYCOL 60 S or POLYCOL 60 LS to the mixture.

- For fresh and salted water.

COMPOSITION

Blend of tension-active foaming agents and specific additives.

INSTRUCTIONS FOR USE

And 3 to 7 litres of POLYMOUSSE/ M3 of water.

Pour POLYMOUSSE directly in water.

In unconsolidated formations, first make a drilling mud (1 Kg POLYCOL 60 S or 2 litres POLYCOL 60 LS/ M³ of water) and then add 3 to 7 litres of POLYMOUSSE.

The concentration depends on water inlet in the hole.

Inject 10 to 30 litres of mixture through the drill rods. Then add air while drilling.

In unconsolidated layers, sometimes it is necessary to make an injection every meter. So it is better to inject the mixture through a pump.

POLYMOUSSE is compatible with nearly all kinds of polymers for drilling muds and foaming agents.

MG LUB

USE

Anti-swelling and encapsulating agent for drilling or coring clays.

Prevents hydrating soils, and decreases clogging of bits. Stabilizes the hole walls in clays, maris, etc …

FORM

Liquid form product.

Available in 30 Kg cans.

ADVANTAGES

- Little storage and low concentrations: 1,0 to 3,0 litres/M3 of mud, to obtain good anti-swelling properties.

- Easy to mix: liquid form.

- Stabilize the hole walls and reduce binding on inhole tools.

- Assist removal of casings in sticky clays formations.

- Biodegradable.

- Non toxic, non polluting polymer.

- Better core recovery in swelling formations: reduces hydration of core and hole, prevents core from swelling in the inner tube.

- Better cuttings removal.

- For fresh and salted water.

COMPOSITION

Blend of sodium polyacrylates in 35% aqueous.

INSTRUCTIONS FOR USE

Pour the product directly in the tanks.

Determine the concentration:

- 1,0 to 2,0 litres/M3 for rock bit drills.

- 2,0 to 3,0 litres/M3 for core recovery in sticky, swelling or plastic formations.

Pour MG LUB directly in water. The mud is ready immediately.

When drilling, the polymer deposits on the sides of the hole, core and the cuttings to encapsulate clays and marls. So it is necessary to add product time to time: 1,0 litre/M³ of mud every 5 meters.

MG LUB is compatible with nearly all kinds of polymers for drilling muds.

MG LUB is incompatible with bentonite and attapulgite muds.

Copyright Geotechno 2026 -